Plexiglass Acrylic Sheets: The Safer and Better Option For Your Projects

Plexiglass acrylic sheets are one of its kind material that has many benefits and is far superior to regular glass or other plastics. You see, these sheets are highly appreciable for their outstanding safety measures and being user-friendly as fabric long-lastingly used in multiple applications. Learn more about the benefits of using plexiglass acrylic sheets and how they are shaping up to be a revolutionary in different sectors.

Pros of Plexiglass Acrylic Sheets

Plexiglass acrylic sheets are very light but much stronger than conventional glass, one of the greatest benefits. These features combine to make them particularly suited for an application where safety is critical. Moreover, plexiglass is far more flexible than glass so it can be easily cut into shape and bent. In addition, these sheets offer all the age resisting and UV protecting characteristics prolonging defense to outdoor elements.

Design and construction innovation

The introduction ofp plexiglass acrylic sheets has launched a new era in the safety, construction and design fields. The uniform quality of acrylic sheet allows for the inventive potential that would be impossible using conventional media. Acrylic Sheets For Creative DesignPurchasing acrylic sheets allows designers and architects to tap into their creative well as these offer them the much-needed transparency and clarity that no other material with this degree of design flexibility. This also ensures quicker adaptability, making a large variety of designs easily attainable for any project.

Safety and Reliability

Emphasis on Safety - Security wise, plexiglass acrylic sheets are a simply better option. This makes the sheets safer than traditional glass since they do not break into shards of great injury potential. This safety feature makes high-traffic spots such as hospitals, schools and public buildings the best place to use plexiglass acrylic sheets. Furthermore, their robustness also makes them resistant to accidental hits which was another of the reasons for replacing very frequently.

Applications - Plexiglass Acrylic sheets are used in a variety of markets including signage, displays, windows and skylights as well as furniture. Due to their versatility, they can easily be installed into any indoor or outdoor project making them perfect for residential and commercial use. Luxigraze panels are custom made from colored & textured Acrylic sheets which make our design more versatile in terms of color and finishing options.

Ease of Use and Maintenance

Plexiglass acrylic sheets are very easy to use whether you're a professional or an amateur. Scoring the material is just like cutting drywall - you cut through one face and snap it against itself along that line. You can drill the holes using a regular drill bit, but be careful not to crack or melt anything. Finally, Novak shows us how to sand and polish the edges for a professional finish using nothing more than some basic tools like that of an edger sander or buffing wheel.

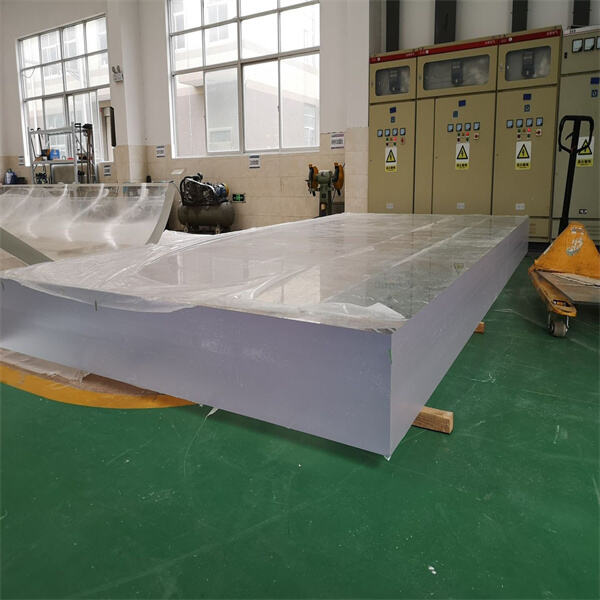

Deliverability is synonymous with logistics and this company places a significant emphasis on providing high-quality goods or services to fulfil the variances of demand among our customers. Not only are our acrylic sheets fabricated with advanced manufacturing techniques to deliver unbeatable strength and utility, we also offer an array of customization options - from colors & finishes to custom cuts. We are together to make sure it is available for whatever your project requirement with the best service and support.

Commonly used in construction, medical and industrial applications protective plexiglass acrylic sheets are an excellent answer to your needs. It is used for skylights, sound barriers and safety shields like in a hockey rink as well as in marine windows; this speaks about the wide array of applications where it comes out good.

So that PYRAVITAILLE plexiglass acrylic sheets are the most beneficial to look at rather than standard glass, or some other plastic material. They also have various operational options, safety features and are known for being user-friendly which makes them an ideal selection in multiple project plans We are fully prepared at our enterprise to assist you in finding the right plexiglass acrylic sheet for your projects. We offer many customization features as well as great customer service to aid you in completing your project. Contact us to get started with the right levels/max min values for you.

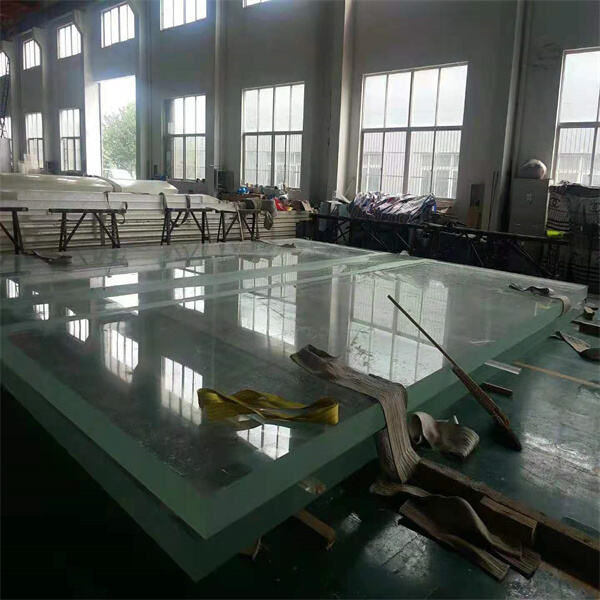

plexiglass acrylic sheet have a transmittance of more than 93 93%. 100 93% purity MMA is imported directly from Mitsubishi Lucite. CNC cutting brings more precise dimensions. Each panel is smooth, flawlessly polished surface. More seam strength(if any) After splicing, the panel is annealed which results in stronger strength and aesthetics. The internal stress in acrylic panels that are tempered is removed through annealing. We perform a rigorous check under lighting for each panel before packing. To exceed the client's expectations We pay particular attention to each detail of the manufacturing process.

Our team is comprised of more than 20 years of experience in the industry and can respond quickly to clients' requests. It doesn't matter if you're a professional contractor or a end user, our sales team members can be in constant conversation with you. Additionally, the design team are able to offer scheme proposals quickly. For urgent project, we try to provide flexible managing and quick delivery. With years of experience and knowledge, we are able to provide the client to find the plexiglass acrylic sheet.

Lanhu offers plexiglass acrylic sheet solutions for aquariums including acrylic material fabrication LSS equipment, onsite installation and commissioning. With our professional design team, we are able to do public aquarium planning design as well as development and construction design. Our factory produces thick acrylic panels (40-800mm) that can be used to construct oceanarium tunnels and windows. We design life-support systems for large aquariums, and supply equipment at competitive cost. Our experts are able to put equipment in place on site anywhere in the world.

Outdoor anti-UV acrylic panel colors change slightly but it will not fade after 30 years Our acrylic panels comply with industry standards and country standards We offer a 30-year guarantee for color changes in acrylic panels We promise that the colour of acrylic panels will not change significantly over the warranty time and that there will be no obvious yellowing or discoloration