How To Construct An Acrylic Fish Tank

Acrylic is a fabulous material to customize your aquarium at home again suitable for both and stylish when it comes of creating the house natural environment with acrylic fish tank. In this article, we discuss every step of acrylic aquarium builder from Shanghai Lanhu which not only reinforces the attractiveness of your space but also ensures that your favorite aquatic beings can reside there.

The first most important step in your fun DIY project is to decide on the size of acrylic aquarium that you want. Take a moment and consider what dimensions will work best for your space, as well as all the little fish guys or gals that you plan to house in this tank structure before we dive into construction. The fish tank must be located in a place that will have enough space to combat the weight of water; also, sunlight should be present so opt for building an acrylic aquarium from Shanghai Lanhu.

Gather Your Tools and Supplies for the Project

Now that you have decided on the right dimensions of your aquarium, it is time to collect all the equipment and tools needed in order to make what was imagined for this fitted size. Invest in top-quality acrylic sheets, a proper bonding agent for adhesion, sharp blade saw-cutting blades power drill to strengthen bond clamp supporter ruler to measure accuracy and silicone sealant so you can be rest assured of the assembly.

Now that everything needed has been bought, you will have to cut the acrylic sheets (using a saw) in precise dimensions. There is also a science and reason why precision cutting of the sheets must be in spot to make sure they are prevented from cracking or chipping, not just will it preserve your aquarium searching very good but most importantly it could hold your fish mates safe as well so opt for building acrylic aquarium from Shanghai Lanhu.

When you start assembling by bonding the acrylic sheets, then make sure use clamps and braces for supporting them properly. These should be evenly spaced to lock in position when secure and will keep your fish tank sturdy. Use an appropriate adhesive to weld round up with those sections and strengthen the structural strength of tank.

You could help waterproof the shelter, but using a modest amount of silicone sealant over each completed piece.

Use this method to seal all the water joints on the exterior of your acrylic aquarium, sealing it with silicone into a watertight finish. This level of detail and precision in the application not only stops leaks but can act as a testament to your work where others may look at it, knowing you took care building this tank with that extra step to assure quality acrylic tanks.

The following tips are recommend by experts to keep your tank water crystal clear.

In order to have an acrylic fish tank, one of the best possible ways is to make sure that you follow some or all of this expert advice and The Ultimate Guide for Proper care and Maintenance.

This is where you will need high quality acrylic sheet that is durable and tough enough not to crack easily.

This will be very helpful while measuring also to avoid any chances of leaks or damaging the built of your aquarium.

Follow the recommendations for bonding agents to ensure that a good bond is established.

Use a soft cloth to clean and maintain your acrylic aquarium builders periodically for preservation, as well scratches can lead them down the path of deterioration.

Acrylic Aquariums:

Pros: Lightweight, large field of vision (increased visibility), can be molded into various shapes so opt for aquarium tank acrylic.

Cons: prone to scratches, might need more care and cleaning in the long run (stainless steel), can be expensive up front.

Acrylic panels have a transmittance of more than acrylic aquarium build. 100 Pure MMA obtained directly from Mitsubishi Lucite. CNC cutting brings more precise dimensions. Each panel is flawlessly polished and has a smooth surface. If needed, stronger seam strength is achieved After splicing, the panels are annealed for better strength and aesthetics. Annealing can remove internal stress of acrylic panels which are heated in oven. We ensure that we conduct an exact check under lighting for each panel prior to packing. We care about every detail during process of production to meet the client's expectations.

Our team has over 20 years of industrial acrylic aquarium build and can be responsive to client requests. Whether you are a professional contractor or an end-user our sales representatives will always be in communication with you, and our design team members can provide scheme proposal drawings quickly. We'll do our best to manage urgent projects and ensure they are completed in a timely manner.

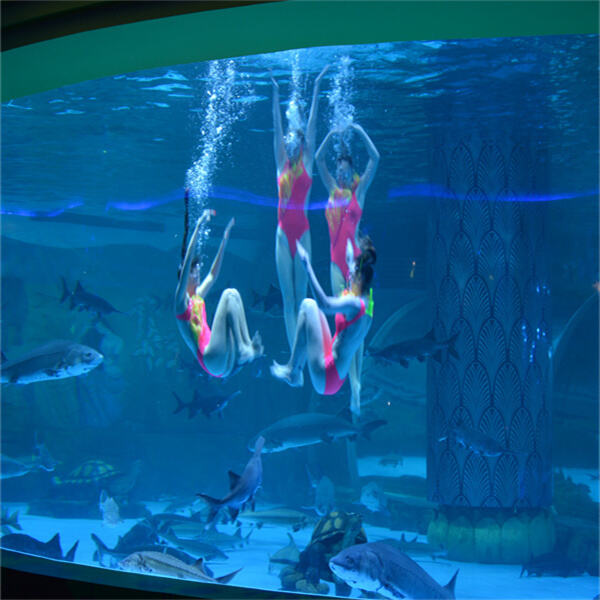

Lanhu can provide turnkey solution including aquarium design as well as acrylic aquarium build LSS equipment supply, and onsite installation and commissioning. We have a design staff which can offer public aquarium development, planning, and design concepts for construction. Our factory manufactures thick acrylic panels(40-800mm) for oceanarium windows and tunnels. We are able to design life support systems for aquariums with large sizes, and provide equipment at competitive cost. If necessary, our experts can install on-site all around the world.

Color of outdoor anti-UV panels will alter slightly however they won't turn yellow after 30 years The acrylic panels we provide are in line with the relevant standards for the country and the industry standards We offer a 30-year guarantee on acrylic panel color changing We promise the color of our acrylic panels will change little during the warranty time and there will not be obvious yellowing or turbidity

Advantages: affordable option, resistant to scratches and lairds, transparent visibility.

Cons: Fragile, Small Number of Styles Available And Non-Amplified

With these steps and the expert suggestions that come within, you too can design an exquisite custom acrylic aquarium which will add value to your space and be a viable home for fishes.